The standard assurance shall confirm the compliance of all the outcome attained for the ultimate rinse and swabs, which need to be a lot less than the acceptance conditions proven.

When the cleaning treatments, sampling strategy, and validation protocol are established, manufacturers can execute the cleaning validation course of action. This will involve undertaking the cleaning technique According to the developed protocol, gathering samples at designated locations, and analyzing the samples for residual contaminants.

Purified h2o shall be used for a final rinse for products, to be used within the production of non-sterile solutions.

Swab sampling is a straightforward sampling method exactly where a sterile swab is accustomed to wipe a particular area with the machines’s floor. The swab is then subjected to extraction and analysis to detect any residual substances.

In advance of initiating the cleaning validation method, brands really should carry out a hazard assessment to detect probable resources of contamination and identify the level of chance related to Each individual resource.

Due to our Extractables Simulator, we can offer you rapid provisioning and rapid turnaround of extractables validation. Despite having calculations manufactured on sophisticated assemblies, knowledge is usually obtainable in fewer than 1 week. 10 weeks for extractables or leachables tests.

Ongoing monitoring: The performance and regularity with the cleaning procedure need to be continuously monitored. Periodic validation and frequent checking are required to be sure compliance with regulatory standards.

Observe: This method makes it possible for sampling of a giant area, of regions which can be inaccessible or that cannot be routinely disassembled and presents an Over-all image.

If a person tools chain has goods which are common for one more tools chain, and if the area area of the previous is bigger when compared to the later on,

Cleaning validation during the pharmaceutical industry involves a variety of jargon and abbreviations that are crucial for production staff to be informed about. Allow me to share twelve frequent conditions associated with cleaning validation and their definitions:

These cleaning methods Perform a crucial part in making certain that tools surfaces are completely cleaned and free of charge from contaminants, Hence reducing the potential risk of product contamination.

I want to enroll in website newsletters from Sartorius (Sartorius AG and its affiliated firms) based mostly of my private pursuits.

• the analytical methods (specificity and sensitivity) such as the Restrict of detection and the limit of quantification;

Pharmaguideline is actually a pharmaceutical web site wherever pharmaceutical concepts are spelled out in quite simple and easily here understandable language for gurus and students. All content articles and SOPs are prepared by Ankur Choudhary.

Susan Dey Then & Now!

Susan Dey Then & Now! Tina Majorino Then & Now!

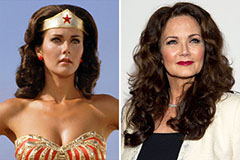

Tina Majorino Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now!